| | Newsletter - April 2003

Appeal

Donations to the fund have slowed over the winter months, but with the new

season starting it is hoped that things will pick up shortly. Driver for a Fiver

has restarted over Easter and has provided a boost in income. It is unfortunate

that the problems with the shed roof prevent access to the workshop viewing

gallery which as well as allowing the public a closer look at the work going on,

also provides a regular stream of donations.

The time is approaching when we will need to spend some significant amounts

of money on new materials for the E1's boiler. We are still hoping that someone

will step forward to take on the job of fund raising to ensure that the job is

not delayed by lack of funds.

|

A job which boosted the appeal fund at the end of last year

was the overhaul of pistons, crosshead and slide bars for a loco at the

Swindon and Cricklade Railway. The pistons were originally fitted with

some unusual piston rings but finding new ones to the same design would

have been very difficult. Conventional square section rings were obtained

from the Severn Valley and to support them some special spacers were

machined and nickel plated. Here a piston is being drilled to enable the

spacers to be fixed in postion. |

GWR 56xx

No. 5637

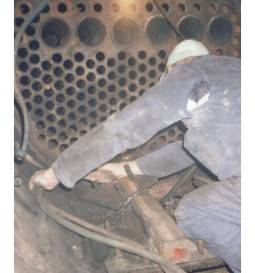

| The main task in the Workshop over the winter has been

completing the retube of the 56 in time for the new season. At the same

time the safety valves have been repaired and 10 stays replaced as part of

the 14 month boiler inspection.

The picture shows Jeff using the gas axe to cut out some tube ends in

the smoke box. The six larger superheater flues at the top of the picture

did not need to be replaced. |

|

|

|

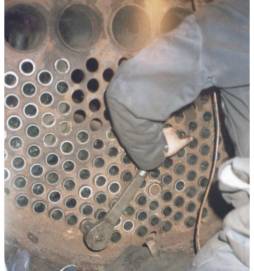

To ease the job of expanding the 218 small tubes, normally

laboriously wound up by hand, we used an air wrench. Dave is using it in

the 56's firebox.

One tube, shown ringed with chalk, is slightly larger than all the

others. This is not a mistake! But is to allow easier removal of stubborn

tubes. |

| Since the air tool doesn't give much of an idea of when the

tube has been expanded far enough, final expansion is completed by hand.

Here Jerry is expanding the bottom tubes in the smokebox.

Working in the smokebox is particularly uncomfortable as it often

involves kneeling amongst studs and other obstructions. The blast pipe and

steam pipe holes were covered with wooden boards to prevent dirt and

debris entering the valves and cylinders. |

|

LB&SCR E1

No.110

Recently all the attention has been on the 56 and 30075 but work on the E1

has still managed to move forward slowly. The task to replace the horn guide

bolts is nearing completion and the springs will be overhauled next. When the

springs have been refitted the loco will once again be mobile and can come off

the jacks which it has been sitting on for the last few months.

USA

Tank No.30075

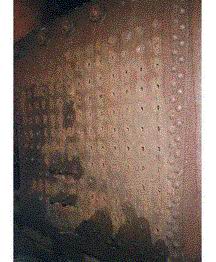

| The boiler has been moved from the loco shed into the

workshops which provides much better working conditions.

The long task of removing the firebox stays is nearing completion. The

picture shows the left hand side of the boiler with all the stays removed.

Every hole will be subjected to ultra-sonic crack detection and repaired

as necessary before fitting the new stays. The boiler inspector has agreed

that it will not be necessary to weld in inserts to reduce the size of the

holes, which will save a lot of work |

|

|

Work on the frames has continued. The saddle has had some

weld repairs and been given a coat of primer as shown in the picture. |

|